MISTRA - The Swedish Foundation for Strategic Environmental Research

MISTRA - The Swedish Foundation for Strategic Environmental Research

Energy efficient reduction of exhausts from vehicles

Quotes from the project "Research Proposal"

Goal“The goal of this project is to demonstrate very low emission levels (0.005 g PM/kWh and 0.1 g NOx/kWh) with an engine exhibiting low CO2 emissions. These levels can be compared with the most stringent legislative levels decided (0.013 g PM/kWh and 0.27 g NOx/kWh). The very low emission levels combined with the high fuel efficiency can be achieved by using advanced components such as innovative catalysts and substrates, reformer and plasma technologies and heat recuperation.”

“The project aims at developing a competence in energy-efficient new aftertreatment systems for combustion engines. The methods are independent of the fuel (i.e. bio-diesel, DME, fossil diesel), but are directed towards engines with excess oxygen, since these systems appear to produce the lowest CO2 emissions also when used with renewable fuels. Although highly efficient, diesel engines produce a lot of waste heat, which can be utilized [...]. This will lead to further decrease in CO2 emissions. The project uses five recent technology advances:

Thermoelectric materials for heat recuperation, catalytic reduction of NOx using hydrocarbons from the fuel, low temperature plasma, fuel reformers with high efficiency and innovative catalyst substrates for minimized heat losses in the after-treatment system.”

"The programme consists of 7 individual component projects. Each project is vital for the integrated result."

The projects are:- Catalytic reduction of Nox

“In order to reduce NOx in oxygen excess, selective catalytic reduction is required.” “[...] attractive solutions for lean NOx reduction include selective reduction using fuel hydrocarbons or derivatives from the fuel, and NOx storage catalysis.” - Reformers for hydrogen production

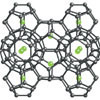

“This part covers an investigation concerning catalytic reforming of various fuels suited for use in heavy-duty applications, such as low-sulfur diesel fuel (Swedish Environmental Class 1) and dimethyl ether (DME). The focus will be on reforming catalysts and reformers where these catalysts will be evaluated and utilized.” - Thermoelectric materials

“The intention of this component project is to research the area of new highperformance thermoelectric materials with emphasis on those that have appeared through recent efforts within extensive programs in the US, Japan and EU.” - Low temperature plasma

“A simple and reliable system for an efficient gasification of carbon particles can either complement or even replace the mechanical filtering. For the carbon particulate removal it is proposed to employ special abilities of non thermal plasma sources and/or plasma applicators.” - System validation and integration

“The system validation will integrate the results from the five technology development tasks:

Catalytic reduction of NOx

Low temperature plasma

Reformers for hydrogen production

Thermoelectric material and devices for power generation

Metal powder filters” - Thermoelectric devices for power generation

“The use of TE power generation (TEG) in vehicles will increase the total efficiency of the engine since the heat losses are used as the heat source for the TEG. Efficient TE devices converting waste heat into useable electricity would significantly lower the fuel consumption, and the potential impact on the reduction of world CO2 emission is sizeable.” - Metal Powder Filters

“One way of removing particulates is through a Diesel Particulate Filter (DPF). These filters have to be able to efficiently absorb the particulates and then regenerate themselves in order not to fill up and cause increased fuel consumption through a build-up of back pressure. An efficiently function filter body is vital to reach the low particulate requirements set up by the project.”

Participants

Programme manager: Heije Westberg, Volvo Technology AB Academic partners:

- Competence Centre of Catalysis (KCK), Chalmers University of Technology

- Department of Chemical Engineering and Technology, KTH - Royal Institute of Technology

- Applied Surface Chemistry (TYK), Chalmers University of Technology

- Plasma group at Ångström Laboratory, Uppsala University

- Volvo Technology AB

- Höganäs AB

- Termo-Gen AB

All contents belong to Termo-Gen AB (© 2008) unless otherwise stated and may not be used without permission

E-mail: info@termo-gen.se | Webmaster: info@termo-gen.com